Aluminum Once Worth More Than Gold: How Magnesium-Aluminum Alloys Are Powering the Next Industrial Revolution: It is almost unimaginable today, yet there was a time when aluminum was more valuable than gold. In the mid-19th century, the French elite dined with aluminum cutlery, while the less fortunate could only hope to touch gold. Aluminum’s rarity was not born from scarcity in the Earth’s crust; it was the extraordinary difficulty of isolating it that rendered it a near-luxury metal. Only the genius of the Hall-Héroult process, independently developed by Charles Hall in the United States and Paul Héroult in France in 1886, democratized aluminum, transforming it from a precious curiosity into a cornerstone of modern industry.

Today, the world faces a comparable industrial pivot. Aluminum, the metal that once symbolized wealth and status, has become indispensable yet constrained. Despite being the second-most consumed structural metal in the world, aluminum faces a triple crisis: soaring energy costs, regulatory pressures from carbon reduction mandates, and declining high-grade bauxite reserves that are increasingly difficult and environmentally intensive to extract. Scarcity, once again, drives value—but this time, the scarcity of sustainably produced aluminum.

Amid this evolving landscape, magnesium emerges not as a mere alternative, but as the defining metal of the future. Lighter than aluminum by a third and far lighter than steel, magnesium enables transformative weight reductions without compromising structural strength or safety. When alloyed with aluminum, magnesium produces materials that are stronger, thinner, vibration-dampening, and electromagnetically resilient. Magnesium-aluminum alloys are no longer theoretical—they are already reshaping the industrial landscape, from electric vehicles to aerospace, high-performance machinery, and next-generation energy storage systems. They are the unsung heroes of the green industrial revolution.

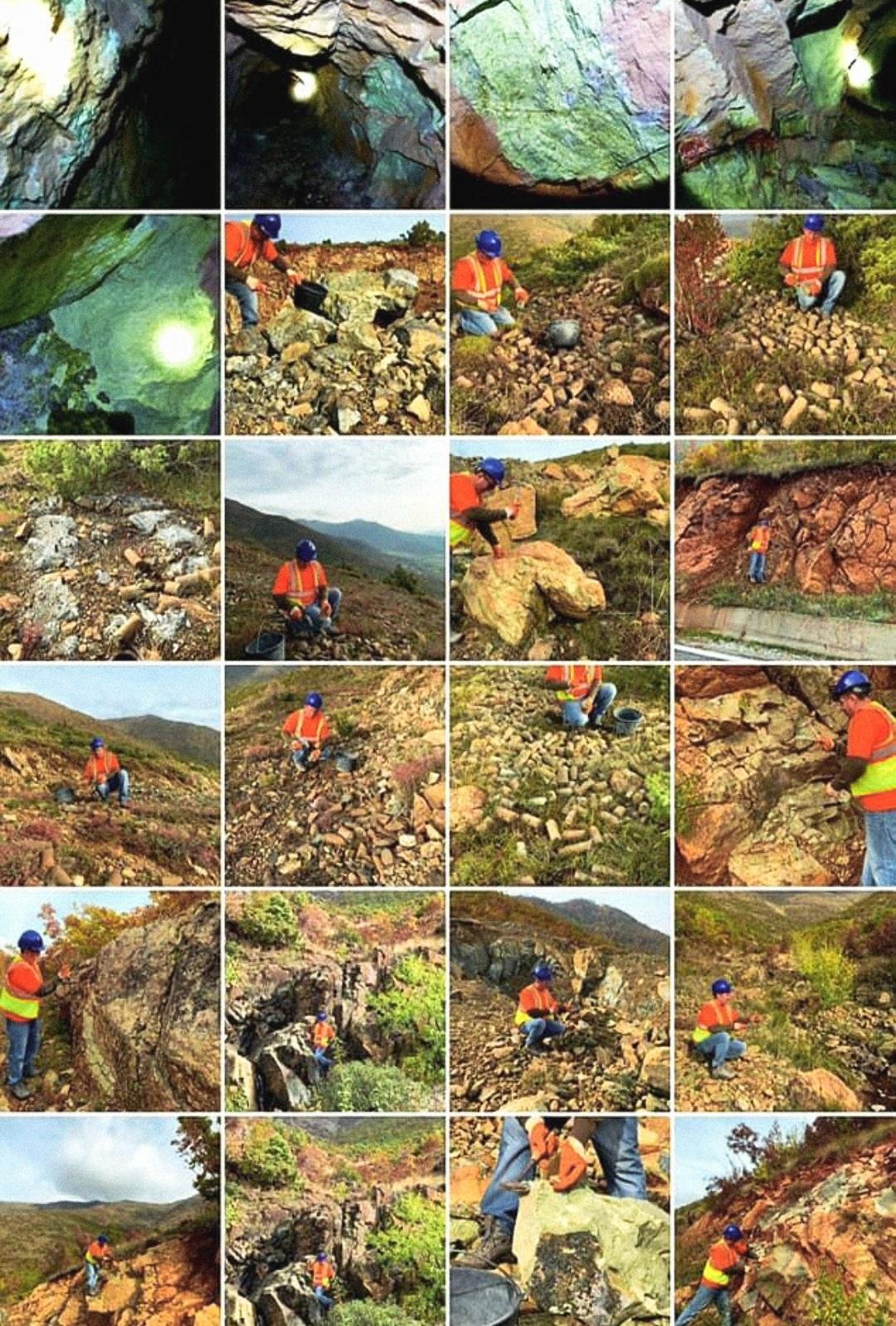

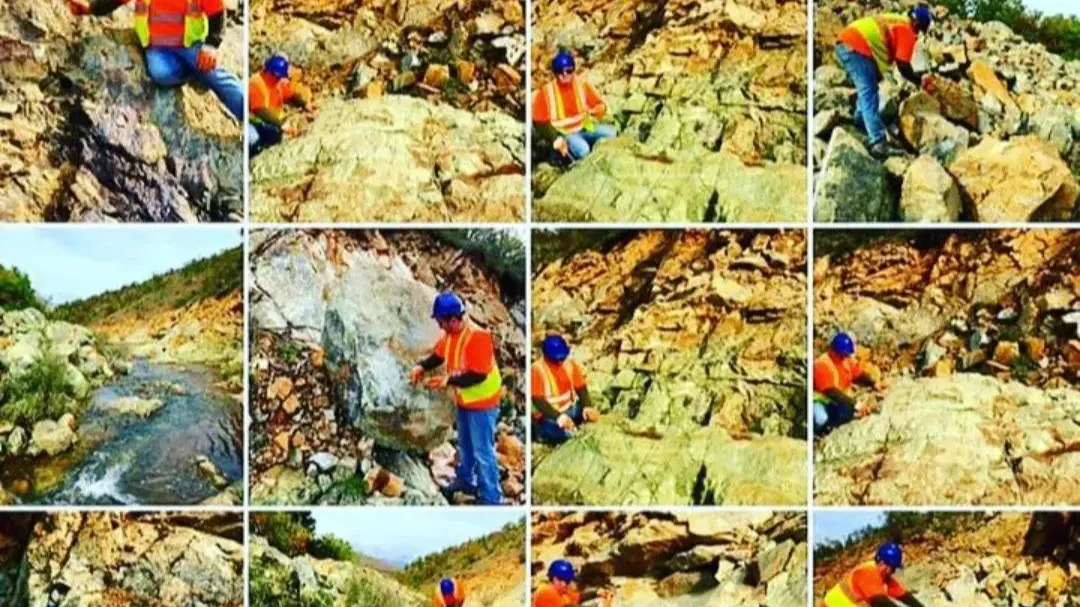

At the forefront of this transformation is Albanian Minerals, whose CEO, Sahit Muja, has declared a mission to redefine the way the world produces and uses metals. “Magnesium is no longer a supporting actor—it is the star of the next industrial era,” said Muja. Albanian Minerals holds the world’s largest high-grade magnesium reserves, a sovereign-scale resource with the potential to power a global shift in structural metals for decades. But Muja emphasizes that holding a resource is not enough. The company is pioneering zero-carbon magnesium production technology, leveraging renewable energy and closed-loop chemical processes to eliminate CO₂ emissions entirely. “We are not just mining a metal,” Muja said. “We are building the foundation for a sustainable, transformative industrial era.”

The strategic applications of magnesium-aluminum alloys are already evident in some of the most technologically advanced machines on Earth. The B-2 Spirit, the world’s most expensive aircraft at $2.2 billion, relies on magnesium and aluminum alloys in precision applications to achieve unmatched stealth, structural integrity, and mission endurance. Magnesium’s critical role in MagRAM stealth coatings reduces maintenance while preserving a minimal radar signature, while magnesium-alloy internal housings cut structural weight, enabling the B-2 to carry its massive 40,000-pound payload with maximum efficiency. These nuanced, meticulously engineered uses illustrate how magnesium transforms performance where every kilogram and millisecond count.

“Every kilogram of magnesium alloyed with aluminum is a multiplier for performance, sustainability, and innovation,” said Muja. “From aerospace to automotive, from industrial machinery to energy storage, magnesium allows us to do more with less—less weight, less energy, less carbon, but vastly more capability.”

The industrial and environmental implications are staggering. Magnesium-aluminum alloys allow for components that are lighter yet stronger, thinner yet more durable, and inherently more energy-efficient. Vibration damping properties are up to ten times better than aluminum, making these alloys ideal for high-performance vehicles and industrial machinery. Electromagnetic shielding capabilities protect sensitive electronics, critical in electric vehicles, aerospace systems, and renewable energy infrastructure. Replacing traditional aluminum with magnesium-aluminum alloys can reduce material-related CO₂ emissions by over 90%, accelerating corporate and national climate objectives. These alloys are not merely materials—they are enablers of a green economy, transforming raw magnesium into high-value, sustainable products.

Europe is uniquely positioned to capitalize on this shift. With its focus on renewable energy, sustainable transportation, and circular industrial strategies, the continent can leverage Albanian Minerals’ high-grade magnesium reserves to reduce import dependence while driving advanced manufacturing and industrial innovation. “This is a sovereign-scale opportunity,” said Muja. “Magnesium is not just a commodity—it is strategic infrastructure for a sustainable industrial future.”

The path ahead is ambitious. Albanian Minerals plans a pilot zero-carbon magnesium production project in 2027, a transformative initiative that will demonstrate industrial-scale, carbon-free magnesium production. “We are proving that zero-carbon magnesium is not only feasible, it is scalable and transformational,” Muja explained. “We are not measured by tons or revenues alone, but by the industries we help transform, the emissions we prevent, and the new economy we help build.”

The story of magnesium-aluminum alloys is, in many ways, a story of vision, foresight, and courage. It is a story reminiscent of the moment aluminum became cheaper than gold—a moment when scarcity, innovation, and audacity collided to redefine what was possible. Today, magnesium-aluminum alloys represent the next frontier: lighter, stronger, cleaner, and ready to empower an electrified, carbon-free world.

For investors, industrialists, and innovators, the message is clear: the green metal revolution has begun, and those who act decisively will shape the global industrial landscape for decades. Albanian Minerals, under the leadership of Sahit Muja, is not merely participating in this revolution—it is leading it. “With the world’s largest high-grade reserves, visionary technology, and an unwavering commitment to sustainability, we are writing the first monumental chapters of the magnesium era,” Muja said.

The age of magnesium has arrived. It promises lighter vehicles, stronger structures, cleaner energy, and a sustainable future for generations to come. And as the industrial world stands at this unprecedented crossroads, one thing is certain: magnesium is no longer the quiet cousin of aluminum—it is the metal of the future, and Albanian Minerals is forging its path.